CUP LOCK SCAFFOLDING

Cup Lock scaffold is a tubular system scaffold that uses the cup and blade locking mechanism for a fast, safe, and efficient erection and dismantle process at industrial construction and maintenance projects worldwide.

The system is composed of vertical standards, horizontal (ledgers), and diagonal braces, designed and manufactured to support heavy loads.

Download Catalog

DSS CUP LOCK SCAFFOLD SYSTEMS

Designed to be versatile and durable. From clamps and adapters to trusses, vertical and horizontal standards, our multipurpose scaffolding systems are easy to maintain and provide quick and easy access for construction and repair projects

NEW DSS ENCLOSURE SYSTEM PANEL (ESP)

The DSS Enclosure System Panels (ESP) are designed to improve security and manageability for standard scaffold configurations utilizing DSS cup lock and ring lock systems. These panels can be used with multiple bays and are stackable, allowing for customization to meet specific requirements.

TUBE SPECIFICATIONS

Tube specifications refer to the requirements for the metal tubes that are used to create the vertical standards and horizontal ledgers of the cup lock scaffolding system. These tubes are made from high-strength steel and are designed to meet specific size and strength requirements.

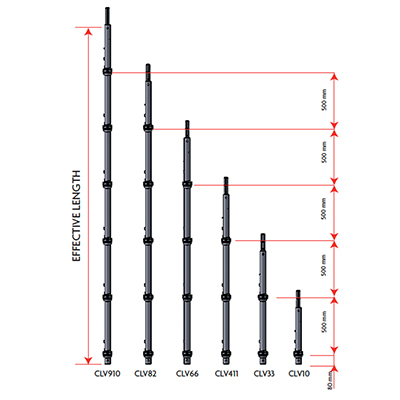

VERTICALS (STANDARDS)

Cup lock scaffold verticals, also known as standards or uprights, are the vertical metal tubes that form the backbone of the cup lock scaffolding system. They provide the primary support for horizontal ledgers and working platforms.

Cup lock scaffold verticals are essential for ensuring the stability and safety of the entire scaffolding system

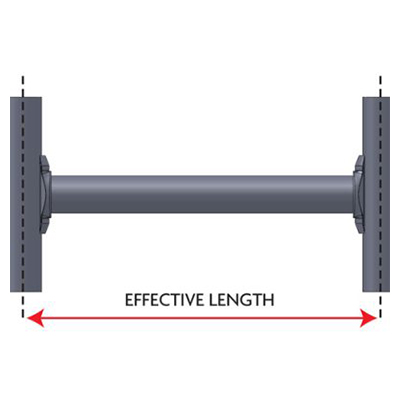

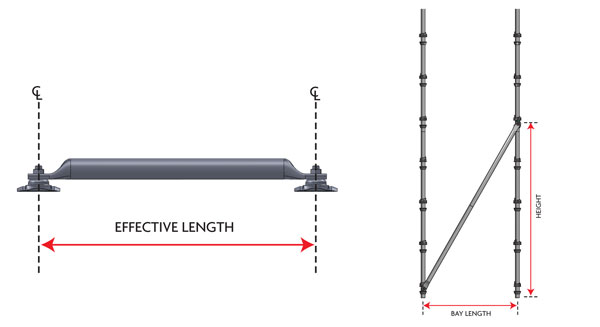

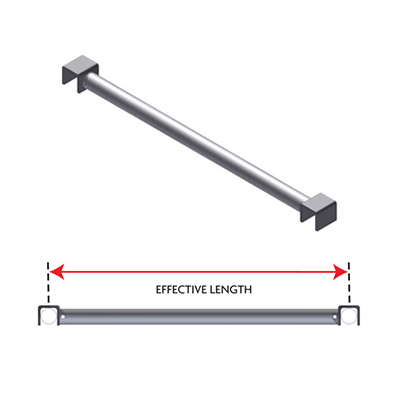

HORIZONTALS

The horizontal ledgers serve as essential connecting elements in your cuplock scaffolding system, linking vertical standards to establish dependable working platforms. These precision-engineered metal tubes form the backbone of your decking support structure, ensuring workplace safety and stability.

These horizontals deliver consistent performance under demanding conditions, supporting your decking and planks while maintaining structural integrity throughout extended use. Your working platforms remain stable and secure, allowing workers to perform their tasks with confidence.

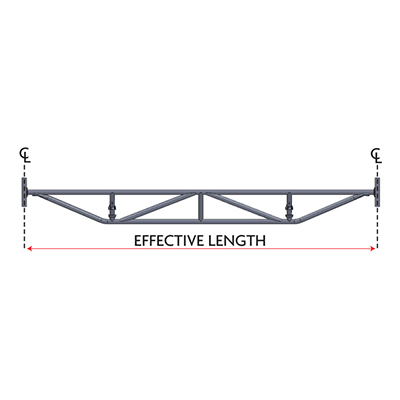

TRUSSES

Cup lock trusses are used in construction and maintenance projects.

They are known for their increased load-bearing capacity and larger spans when compared with the standard cup lock horizontal ledgers.

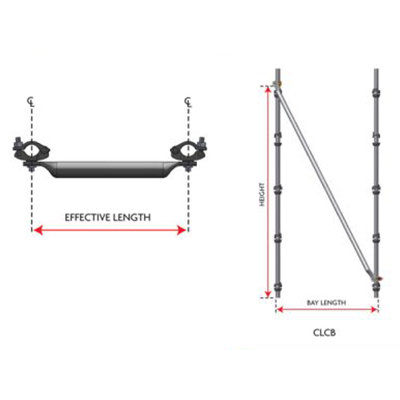

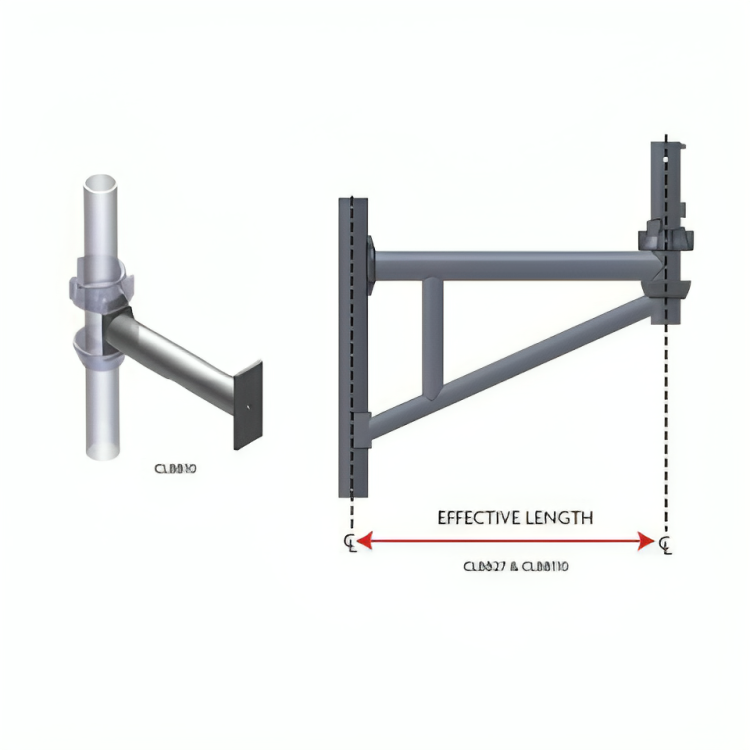

CLAMP BRACES

Clamp braces consist of two steel tubes with cup lock fittings at each end, which are designed to be installed on cup lock verticals. The brace tubes are connected using a swivel clamp, which allows for adjustment to the desired angle.

Cup lock braces clamp are engineered to resist lateral loading on scaffolding – mainly caused by winds – preventing it from swaying or buckling under the weight of workers, equipment, and materials.

FACE BRACES

Cup lock face braces are used to provide lateral stability to the scaffolding system, preventing it from swaying and laterally displacing due to the weight of workers, equipment and materials during windy conditions. They are typically installed in a vertical position, parallel to the face of the building and fit different scaffold configurations.

From a structural standpoint, these braces are preferred over placing a clamp on diagonals.

BOARD BRACKET

The steel plate design of our board brackets integrates a secure cup lock fitting that connects directly to your vertical standards. Each bracket extends horizontally to support wooden boards, giving your team the stable working platform they need. As leading cup lock scaffolding suppliers, we’ve engineered these components for maximum safety and durability.

Cup lock board brackets are typically installed at regular intervals along the scaffolding system to support the wooden boards, which can be easily secured in place using board retaining clips. The brackets are available in different heights, allowing for flexibility in creating the desired working surface.

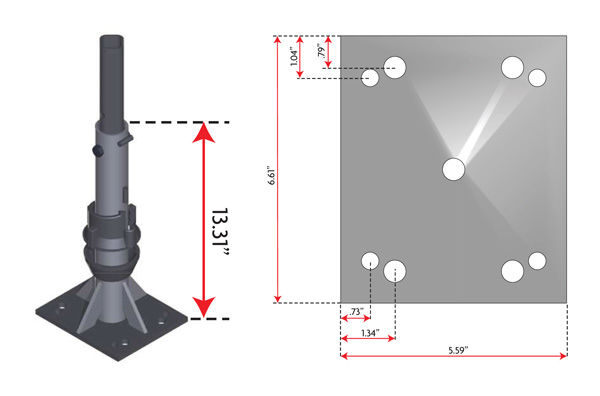

CASTER ADAPTER

Caster adapters consist of a steel plate with a cup lock fitting, which is designed to fit onto the vertical standards of the scaffolding system. The plate has a series of spaced-out holes that accommodate a caster wheel, allowing the scaffolding system to be easily moved around a job site.

Cup lock caster adapters are supplied with different holes to fit different casters.

DECK ADAPTER

CALIFORNIA GUARDRAIL

Guardrails are used to increase safety and prevent falls.

DSS Cup lock California guardrails are designed to meet or exceed safety standards set by the Occupational Safety and Health Administration (OSHA) in California, some of the strictest in the United States. The guardrails are constructed from high-strength steel and, as per requirements, meet the height requirements laid out by the OSHA in California.

The cup lock California guardrails are easy to install and are compatible with a variety of accessories, such as toe boards and mesh panels, to provide additional safety features.

GUARDRAIL POST

Guardrails are used to increase safety and prevent falls.

DSS Cup Lock Guardrail Posts are used for a variety of applications including to provide vertical support for guardrails at midspan between vertical legs. Every Guardrail Post manufactured meets the highest possible standard of quality provided to our clients.

SUPPORT SPIGOT CLAMP

The clamps are used to connect vertical standards at the midspan of a bay on top of a ledger, truss, lattice girder, etc.

Cup lock support spigot clamps are typically installed in cases where a standard leg is not able to go all the way to the ground, for example when the scaffold needs to clear an entrance to a car garage. This helps to transfer the weight of the scaffolding system evenly and provides additional stability.

ALUMINUM STAIR STRINGER

Aluminum stair stringers give your teams safe, reliable access between scaffold levels. These lightweight components feature end hooks that connect securely to your horizontal ledgers, creating a strong foundation for your stairway system.

Each stringer links with horizontal ledgers to build a stable staircase that helps workers move safely between platforms.

Setup and breakdown won’t slow your project timeline. These aluminum stringers minimize installation time while maximizing mobility around your job site. Your crews will appreciate how easily they can transport and position these lightweight components, especially when configuring access points in challenging locations.

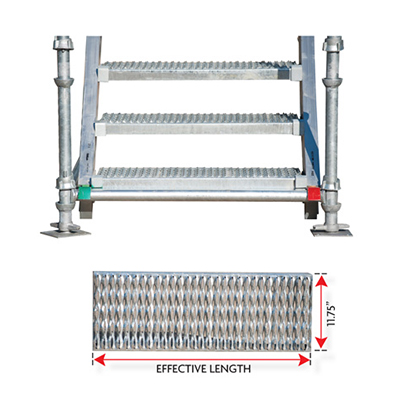

STAIR TREADS

They consist of a horizontal steel platform which fit onto the brackets already installed on stringers. The treads are installed between two cup lock aluminum stair stringers to create a stable and safe staircase for workers to access higher levels of the scaffolding structure.

Cup lock stair treads are designed to be slip-resistant, providing a safe working surface for workers even in wet or slippery conditions.

INTERMEDIATE TRANSOM CUP LOCK SCAFFOLD

This consists of a horizontal steel tube with hooks which are designed to fit onto the horizontal standards of the scaffolding system.

The intermediate transom cup lock scaffold is installed between two horizontals at the mid-span of a bay to provide support for the planks in case there is a need to have a void at some point in the bay.

Purchase Premium Cup Lock Scaffolding for Sale from DSS

If you’re ready to upgrade your cup lock scaffolding equipment, DSS is the solution you need. We bring the highest quality and safety standards in the industry to every product we sell.

Contact our team today to discuss your specific requirements and configurations you need for your next project.