OEM

The DSS OEM team designs, assists in the design, and manufactures top quality scaffold components for our customers to private label and market as their own.

Our engineering teams work closely with our customers to create scaffolding products and equipment to meet their customers’ needs. We aim to engineer and re-engineer components to remove costs while maintaining quality meaning higher margins for our customers.

Our expert engineers work from design drawings or simple concepts to create new and re-engineered products to best fit the needs of our customers’ customers.

We have built an enviable reputation within the industry and work with brand-name scaffolding providers from across the globe producing their shoring, and forming products that cater for the need of multiple industries.

As the original pioneer of OEM scaffold manufacturing, DSS’s capabilities have been subject to rigorous audits and reviews by some of the best manufacturers. DSS factories hold ISO 9001:2015, ISO 14001:2015, OHSAS 18001, and EN 1090 certifications. All components where necessary are tested to the latest ANSI and CSA standards.

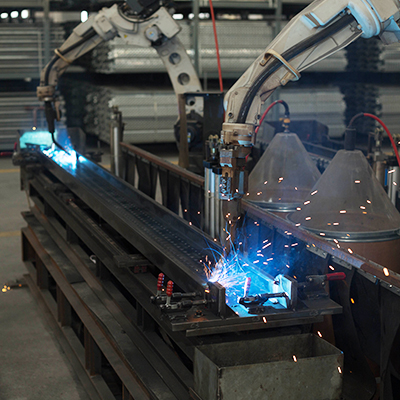

Quality and customer service have allowed DSS to continue to expand its manufacturing capacity to an unparalleled level. DSS ships more than 60,000 metric tons of material per year and is continuously improving and expanding its footprint through factory investments in robotics, advanced roll forms, progressive dies, and improved floor layouts.

DSS is dedicated to constant improvement, safety, and industry awareness to ensure our products remain the first choice for our clients.

MANUFACTURING CAPABILITIES

DSS has an experienced engineering and development team that is committed to ensure all products are managed to the highest standards within the construction industry. Thus, consolidating knowledge to provide the very best solution for all circumstances

- Drafting capabilities – including 3D modeling, Shop/Manufacturing drawings

- FEA analysis – on components

- Material Review – to determine comparable materials using proprietary software

- First Article review and approval process

- QA/QC development process tailored to suit product type (QA plan)

- Reverse Engineering of all product lines

- Design of products to meet customer needs and meet local standards and specifications

- Project Management (PMP qualified personnel)

- Product inspection manuals and procedures

QUALITY ASSURANCE / QUALITY CONTROL

At DSS, we are committed to quality in every step of the scaffold manufacturing process. All the steel we use comes with mill certifications, but we don’t stop there. We use an independent lab to verify that all steel arriving in our factories meets or exceeds the appropriate specifications. With an ongoing QA/QC audit program, our dedicated team of engineers and quality managers, supported by our corporate HQ, promote continuous improvement throughout all our facilities (based on site) thus reducing and eliminating non-conformities.

APPROVALS/ CERTIFICATIONS/ REQUIREMENTS

OUR MANUFACTURING FACILITIES

- All factories hold valid ISO 9001:2015 certification

- Main factories hold both ISO 14001:2015 and OHSAS 18001:2008

- Selected factories hold EN 1090-1:2012, EN 1090-2:2018 and EN1090-3:2019 for Steel & Aluminum Structures

- Selected factories hold ISO 3834-2:2015, ISO9606-1:2012 and ISO 9606-2:2004 for Steel & Aluminum Welding

- OEM specific DIN approvals

GLOBAL REGULATIONS WE MEET

- Ring Lock System-Australian/NZ Registration AS/NZ 1576.1:2010, AS/NZ 1576.3:1995, AS/NZ 1577-2013–

- General Scaffolding and Structural requirementsDICTUS Registration (Chilean Norms – 2501/1 and 2501/2:202)

- Scaffold -Bureau Veritas Registration – EN certifications